Tearing Resistance Testing distribution|Tear Resistance ASTM D1004 : wholesaler A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and suitability of materials under real-world conditions. Resultado da Mi tío All Episodes 2022. Season. 1; All; Overview; 6 Episodes; Official Site IMDB TMDB JustWatch Wikipedia . Ads suck, but they help pay the bills. .

{plog:ftitle_list}

web31 de mar. de 2023 · Para facilitar a vida dos consumidores, a empresa disponibiliza manuais e os Drivers Philco dos equipamentos para os consumidores. Esses drivers compõem o conjunto de softwares de aparelhos que devem ser instalados ou atualizados para garantir melhor desempenho aos aparelhos.

A tearing resistance tester is specifically designed to measure the force required to propagate a tear in a sample material. This measurement is crucial for determining the durability and suitability of materials under real-world conditions.Tear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample's ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test .ASTM D1922: This standard measures the propagation tear resistance of plastic films and thin sheeting. ASTM D689: This standard applies to measuring tearing resistance of paper. ISO .Find out more about the techniques and methods given in these standards for the determination of tearing resistance curves (R-curves) in single-edge notched bend (SENB) fracture .

Tear testing is a mechanical testing procedure used to measure a material’s resistance to tearing. It involves applying a controlled force to a specimen, often with a pre-initiated tear or cut, to evaluate how the material behaves under .ABB’s L&W Tearing Tester uses the tearing principle according to the Elmendorf method, which is the classical method to measure tearing resistance in paper. The instrument now offers .

Tear resistance measures the ultimate force required to tear film or sheet. It is often used for quality control checks or for material comparison where tear failures are possible. Test .This test method is used to evaluate the tear strength of common vulcanized rubbers and thermoplastic elastomers. Tear strength can be influenced by mechanical fibering (surface .The tear strength (resistance) of a particular fabric determines the fabric strength under the static tearing action (static tearing), kinetic energy (dynamic tearing) and tearing on a ‘nail’ of the . Reduction of tear resistance as a consequence of defects in soft biological tissues is relevant for a number of medical problems.

Tear resistance is of vital importance in the various functions of skin, especially protection from predatorial attack. Here, we mechanistically quantify the extreme tear resistance of skin and . When it comes to textiles, tear strength is a crucial factor in determining the durability and quality of fabric. It refers to the resistance of a fabric to tearing under stress or force. Properly measuring tear strength is .The tensile strength of a material is the maximum mechanical tension it can withstand before it cracks. It is given in N/mm² or MPa. The tear resistance of a material, also called tensile strength at break, is the mechanical tensile stress .Tear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample’s ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test speed used in generate the tear. Tear propagation resistance for the purpose of acceptance testing is .

The mean force required to continue the tearing of an initial cut in a single sheet of paper is expressed as the internal tearing resistance. If the initial slit is made in the machine direction, the result is given as machine direction tearing resistance and similarly for the cross-machine direction (ISO 1974). Why measure tearing resistance?

Understanding the Tearing Resistance Tester: An In

Understanding Tear Testing: Methods, Applications

ISO 1974:2012 specifies a method for determining the (out-of-plane) tearing resistance of paper. It can also be used for boards having a low grammage if the tearing resistance is within the range of the instrument. ISO 1974:2012 does not apply to corrugated fibreboard, but it may be applied to the components of such boards.ISO 6383-1:2015(E) 8 Number of test specimens 8.1 A minimum of five test specimens shall be tested in each of the required directions of testing. 8.2 Specimens which show a tear out of line to the extent that the tear reaches one of the edges of the test specimen shall be discarded and further specimens tested (see 11.3). 9 Speed of testing

Tear resistance testing can be found in plastic film, paper and textile industries. Tear resistance is the measurement of a sample’s ability to resist tearing. Tear resistance can be impacted considerably by the speed of the test, e.g. test speed used in generate the tear. Tear propagation resistance for the purpose of acceptance testing is .

The wipe test is used to visualise the distribution of surface pores on coated papers and the partial absorbency on uncoated papers. Both can contribute to uneven printing. The wipe test can therefore be used to find possible causes of mottling. . The tearing resistance, according to Elmendorf, is measured before and after accelerated ageing . Fabric tear resistance is crucial for safety, product durability, and customer satisfaction. The Elmendorf test is a standardized method widely used across industries. It helps quantitatively . The tearing strength tester is an appropriate tool to measure the tear resistance of various materials including textiles and fabric. Types of tear test: Tongue Test; Trapezoid; Elmendorf; Measurement of fabric tearing strength: Elmendorf tear tester: Sample Preparation: First we take specimen of 100 ×75 .

Tear resistance test for heavy duty sheath [ETD 9: Power Cables] UDC 621’315-221-8: 620’176’245 IS:10810( Part17)-1986 Indian Standard [sl . under stress as well as by stress distribution and speed of stretching. This test is carried out to ensure that the sheath has requisite strength to withstand the same. 3. Terminology - The tear .ISO 1974 was prepared by Technical Committee ISO/TC 6,Paper, board and pulps, Subcommittee SC 2, Test methods and quality specifications for paper and board. . This International Standard specifies a method for determining the (out-of-plane) tearing resistance of paper. It can also be used for boards having a low grammage if the tearing .Purpose of a tear test: The overall goal of a tear test is to determine a materials ability to resist the growth of the initial tear or its “tear resistance”. The value of a material’s tear resistance is generally accepted to be the force required to complete the tear so that it has gone completely though the material so that it has been .

Tearing Resistance: Tearing resistance is one of the important properties of a textile fabric. . The strain and load distribution on the surface of the flexible composites was obtained by analyzing the strain and tensile curves on the crack cross . specimen cut in the middle; (c) rectangular – tongue tear test (single tearing); (d .The tear test (e.g. Kahn tear test) provides a semi-quantitative measure of toughness in terms of tear resistance. This type of test requires a smaller specimen, and can, therefore, be used for a wider range of product forms. . This toughening becomes noticeable when there is a narrow size distribution of particles that are appropriately . Current Transformer Winding Resistance Test Connections. Photo: TestGuy. Obtaining Winding Resistance Measurements. When measuring winding resistance, the reading should be observed and recorded once the .

5.1 Tear resistance of plastic film or sheeting is a complex function of its ultimate resistance to rupture. The specimen geometry and speed of testing in this test method are controlled to produce tearing in a small area of stress concentration at rates far below those usually encountered in service.This Complete Guide of the Elmendorf Tear Testing explores tear resistance testing dimensions, application areas, standards, methodologies, troubleshooting, and the future landscape of tear analysis. Key takeaways and practical insights empower informed decisions in material science. Application of Elmendorf Tear Testing in IndustryTearing Strength Tester. Tearing strength testing can be found in plastic film, paper and textile industries. It is used to describe how well a material can withstand the effects of tearing. Elmendorf tear is a common method that is used to test tear resistance. The design block tearing resistance, which is based on the AISC [5] block tearing strength function, governs the design when the distances perpendicular to the bearing force are small enough that the interaction of bearing forces leads to the failure of the area surrounding the bolt group: V eff, 1, Rd = A nt f u + min A nv f u A gv f y / 3 γ .

"Pulp and Paper Testing" Edited by Jan-Erik Levlin And Liva Sōderhjeln Page 1 of 7 Item Number: 0202FIN17 ISBN: 952-5216-17-9 287 pages Contents include: • Single fibers and pulp testing • Paper testing • Uncertainty of testing • Standardization Chapter 1 - .

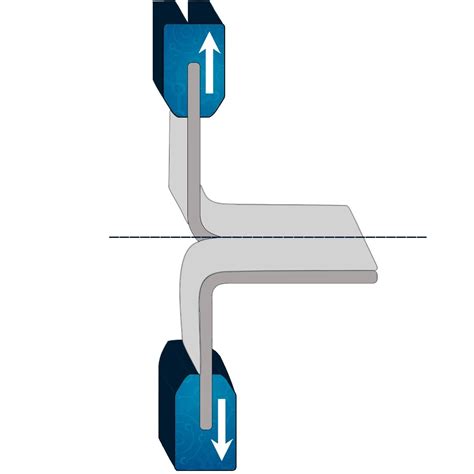

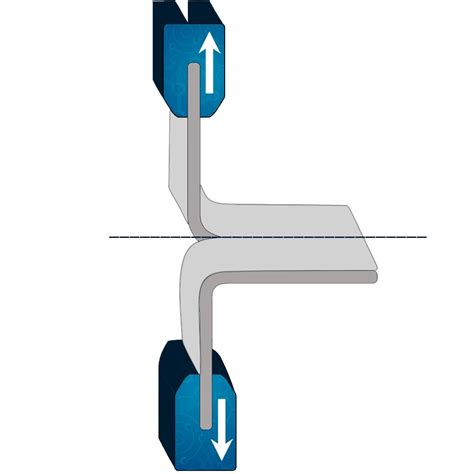

The tear resistance test on fabrics or tear strength is measured to check how the material can withstand the effects of tearing or cuts when in tension. The tear strength is measured as per the ASTM D412 standard test method, which is also used to measure tensile and elongation. The standard test method measures the resistance to the formation . One way to measure tear resistance is through the Pendulum Method or Elmendorf Tear Test, as defined by ASTM D1922. The Elmendorf Tear Test is a simple and reliable way to measure the force required to propagate a slit in a plastic film a fixed distance to the edge of the test sample. The test is performed using a pendulum impact tester, which .Elmendorf Tear (high speed pendulum test) Trouser Tear (low speed using standard tensile test apparatus). Elmendorf tear. The test piece is clamped and a cut introduced such that when the pendulum is released, a tear is propagated from the cut at high speed. The tear resistance is measured as the average force in mN propagating the tear to the . Fabric tear test is mainly used to test the tear resistance of film, sheet, soft polyvinyl chloride, polyvinylidene chloride (PVDC), waterproof coil, braided material, polyene warp, polyester, paper, cardboard, textiles and non-wovens. . Efficient distribution systems and timely delivery schedules have endeared us to our customers spread .

5.1 Tear resistance of plastic film or sheeting is a complex function of its ultimate resistance to rupture. The specimen geometry and speed of testing in this test method are controlled to produce tearing in a small area of stress concentration at rates far below those usually encountered in service.

&Understanding Tear Testing: Methods, Applications

fabric water vapor permeable tester trading

2022 | Maturity Rating: 12 | 2 Seasons | Romance. Teens Charlie and Nick discover their unlikely friendship might be something more as they navigate school and young love in this coming-of-age series. Starring: Kit .

Tearing Resistance Testing distribution|Tear Resistance ASTM D1004